Please note:

* Spur gears with bore or hub dimensions marked * will be discontinued when stocks are depleted.

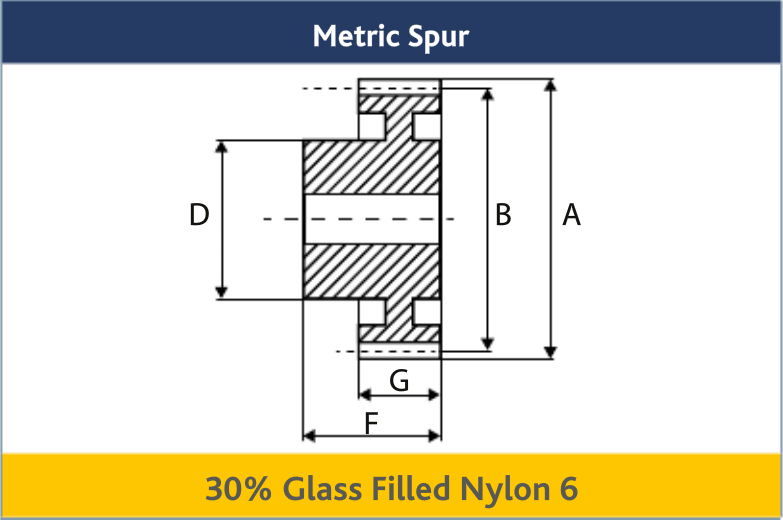

If the required bore and/or hub/boss size is critical please specify when ordering, as some parts may show different size options. All dimensions subject to change. If a dimension is critical to your application please contact our Sales Department for confirmation. For special or reworked gears please contact our Manufacturing Department for a quotation.

It is recommended that when the bores in ‘PS’ Moulded Spur Gears are machined they are machined to the bore size stated or very close to the catalogue size. Boring these Gears to a much larger bore diameter could increase the possibility of discovering small voids or cavities in this area.