Please note:

* Spur gears with bore or hub dimensions marked * will be discontinued when stocks are depleted.

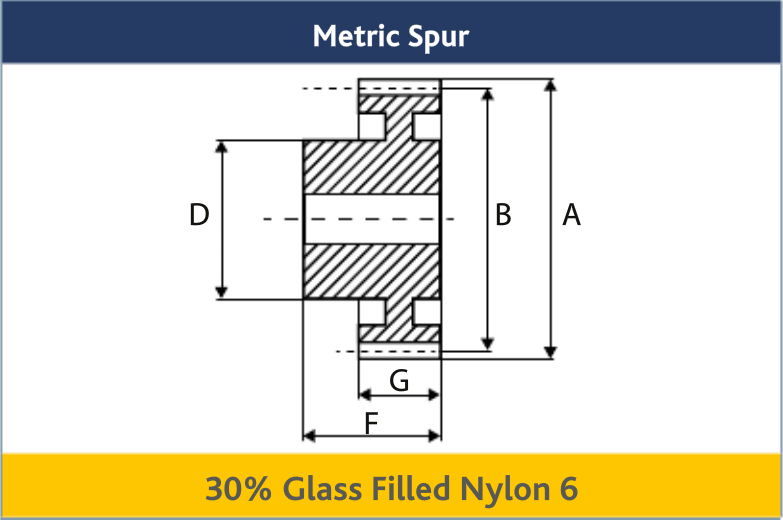

All dimensions subject to change. If a dimension is critical to your application please contact our Sales Department for confirmation.For special or reworked gears please contact our Manufacturing Department for a quotation.