BRECO® ATN – Over 500 tubes of toothpaste per minute

Powerful performance: Two BRECO® ATN polyurethane timing belts transport toothpaste tubes into their packaging in a flash.

More than 500 tubes of toothpaste per minute are transported through a high-capacity cartoner line by two BRECO ATN polyurethane timing belts and finally packaged into their sales packages during transport. The maintenance-free timing belts are equipped with a special cam system which makes time-consuming replacement of the timing belt when changing products unnecessary.

The OYSTAR group based in Karlsruhe is one of the most notable suppliers of packaging machines, technology and services. In 17 locations spread through 11 countries, the group develops, produces and sells individual machines and entire packaging lines used for the fields of primary and secondary packaging. Its machines are used in dairy, food production, pharmaceutics, cosmetics and consumer products.

OYSTAR emerged from the packaging machine branch of what used to be Industriewerke Karlsruhe-Augsburg (IWKA), but its history goes back to the year 1893. In that year, the Dutch colonial minister sent a commission for delivery of “machines for filling and closing tubes” to what was then Batavia. In March 2007 this branch of the company was bought by the German holding company Odewald & Compagnie and subsequently launched as “OYSTAR The Packaging Group”. One of the corporate group’s affiliates is IWK Verpackungstechnik GmbH in Stutensee near Karlsruhe. This “Business Unit Pharma” specialises in tube fillers and cartoners and produces automatic tube filling machines in low, medium and high performance categories.

OYSTAR IWK’s individual machines and packaging lines are equipped with many highly different polyurethane timing belts from the product range of timing belt manufacturer BRECO Antriebstechnik, a company that produces its timing belt range exclusively for the Mulco group. OYSTAR IWK receives on-site support from Hilger u. Kern, Mannheim, with selecting suitable timing belt technology. “This high-capacity cartoner SC 3 is intended for the US market”, Ulrich Weik of IWK Service Engineering tells us, while pointing out visibly American 6.4 ounce (181 g) toothpaste tubes on the supply belt of the machine. This is where the toothpaste tubes supplied by the tube supply system of the high-speed tube filler will be transferred individually into intake compartments once the machine is used for actual production purposes.

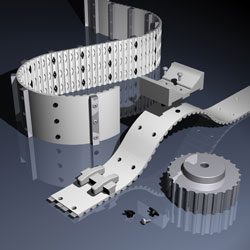

BRECO® ATN Fast installation and replacement

Two BRECO ATN transport timing belts run in parallel in milled guideways carrying over 500 tubes per minute taken from the high-speed tube filler. The profile mountings for the transport trays are screw-fitted flush with each other on the transport timing belts at a spacing of seven cogs each. This makes the use of standard toothed washers possible. Even at this point you can see the strength and flexibility of these polyurethane timing belts especially developed for use in transport technology. The profile mounting fixture in the belt tooth facilitates quick installation and replacement of individually manufactured profiles for special transport purposes or in case of wear and tear.

Running simultaneously with the supply belt, the high-capacity cartoner SC 3 constantly takes printed folding boxes (the weight of the paper is between 250 and 500 g/qm) from a magazine, separates them and erects them for insertion in the filling station where a toothpaste tube is pushed into each box. The dimensions and tolerances of the pre-glued folding box are in accordance with DIN 55222.

Of course, the sales box with the inserted tube now has to be closed at the top and bottom. This is done by a hotmelt station, which sprays hotmelt onto the top and bottom flaps in precise doses. “The hotmelt takes approximately 30 centimetres on the transport conveyor to set. During this time, pressure is applied to the cardboard flaps from the top and bottom,” Ulrich Weik describes this station. “Of course, this depends on the glue used. This is why the transport conveyor is designed to be about a metre long, but this can be changed according to the customer’s requirements.”

If the glue is not as stable as required and the flaps open up again, there is a system to sort out these packages and remove them from the belt. At the same time, this system provides quality monitoring. The glued boxes are also transported by BRECO ATN transport timing belts. These timing belts are equipped with exchangeable sliding cams.

“The cartoner can be converted to process packages containing two or three tubes in an easy, fast process. As the sliding cam system has been adapted for this application and consists of a fixed basic cam installed on the timing belt and a slide-in form cam, the user needs no tools to replace the cams when changing the format. The user also does not need to replace the entire timing belt as used to be necessary when the cams were welded onto the timing belt. New form cams are simply slid into place and the machine line is ready for operation again,” Ulrich Weik describes the advantages of the flexible timing belt system.

A real price advantage

Customer consultant René Preßler of Hilger und Kern emphasises the advantages of using BRECO ATN for the cartoner:

“We use BRECO standard timing belts, including the ATN, in high quantities and offer high availability and variability. This means low downtimes in case of profile changes and finally also low replacement part and installation costs. These are real price advantages. BRECO polyurethane timing belts are a real alternative to using chains in transport technology.”

BRECO ATN polyurethane timing belts are part of a modular system comprised of the timing belts, fastening elements, the BRECO ATN timing belt lock and cams or profiles. FDA-compliant timing belts and belts made from materials flexible at low temperatures for use in ambient temperatures between -25°C and 5°C are also available.