Oregon PU ET Antistatico Hose (911011)

| SPIRALED AIR SERIES |

|

Oregon PU ET Antistatico Hose (911011) is a POLYURETHANE (PU) POLYETHER hose with PVC rigid spiral, copper strand for antistatic rendering, for suction and transport of abrasive materials and dry foodstuffs.

Details

| Features | Value | |

|

Smooth surface | **** |

|

Flexibility | **** |

|

Abrasion resistance | ***** |

|

Temperature range | -25 °C 85 °C |

|

Chemical resistance | Contact TransDev |

|

Crushing resistance | *** |

|

Ozone resistance | ***** |

|

Microrganisms resistance | ***** |

|

Antistatic | Strand resistance 0.075 Ohm/m |

|

Hydrolysis resistance | Resistant to hydrolysis in 60 °C warm water Resistant to hydrolysis in 60°C warm water. |

|

For food | EU according to Declaration of Conformity. |

Specification

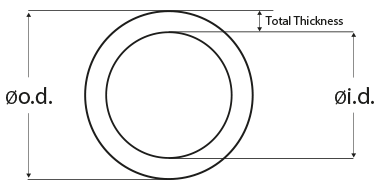

Ø Nominal |

Ø Nominal |

Ø i.d. |

Ø o.d. |

working pressure at 23 °C |

Vacuum

|

bursting press. at 23 °C |

Bending radius |

Total thickness |

Wall thickness |

Ø rigid spiral (AxB if oval) |

Strand Wire in 1 mt |

Spiral pitch |

Spiral

|

Weight

|

Coil length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | mm | bar | m/H2O | bar | mm | mm | mm | mm | m | mm | right/left | g/m | m |

| 25 | 1 | 25.3 | 30.9 | 0.6 | 4 | 1.8 | 25 | 2.8 | 0.5 | 2.7 | 12.5 | 7.2 | right | 190 | 20 |

| 30 | 30.2 | 36 | 0.6 | 4 | 1.8 | 30 | 2.9 | 0.6 | 2.8 | 14.5 | 7.2 | right | 210 | 20 | |

| 32 | 1 1/4 | 32.2 | 38.2 | 0.6 | 4 | 1.8 | 32 | 3 | 0.6 | 2.9 | 14 | 8 | right | 240 | 20 |

| 35 | 35 | 41 | 0.4 | 4 | 1.2 | 35 | 3 | 0.6 | 2.9 | 15 | 8 | right | 250 | 20 | |

| 38 | 1 1/2 | 38.2 | 44.6 | 0.4 | 3 | 1.2 | 38 | 3.3 | 0.6 | 3.1 | 17 | 8 | right | 310 | 20 |

| 40 | 40.2 | 46.4 | 0.4 | 3 | 1.2 | 40 | 3.1 | 0.6 | 3 | 16.5 | 8.3 | right | 330 | 20 | |

| 45 | 1 3/4 | 45.2 | 51.8 | 0.4 | 3 | 1.2 | 45 | 3.3 | 0.6 | 3.1 | 16.5 | 9.5 | right | 370 | 20 |

| 50 | 2 | 50 | 57.4 | 0.4 | 3 | 1.2 | 50 | 3.7 | 0.7 | 3.5 | 16.5 | 10.1 | right | 440 | 20 |

| 51 | 2 | 50.8 | 58 | 0.4 | 3 | 1.2 | 50 | 3.6 | 0.7 | 3.2 | 17 | 10 | right | 420 | 20 |

| 60 | 60 | 68 | 0.4 | 3 | 1.2 | 60 | 4 | 0.7 | 3.7 | 17 | 11.3 | right | 500 | 20 | |

| 63 | 2 1/2 | 63.5 | 71.5 | 0.3 | 3 | 0.9 | 63 | 4 | 0.7 | 3.7 | 20 | 12 | right | 530 | 20 |

| 70 | 70 | 78.4 | 0.3 | 3 | 0.9 | 70 | 4.2 | 0.7 | 4 | 19 | 12 | right | 660 | 20 | |

| 75 | 75 | 83.6 | 0.3 | 3 | 0.9 | 75 | 4.3 | 0.7 | 4 | 19 | 13.2 | right | 660 | 20 | |

| 76 | 3 | 76.2 | 84.6 | 0.3 | 3 | 75 | 4.2 | 0.7 | 4 | 19 | 12.3 | right | 660 | 20 | |

| 80 | 80 | 89 | 0.2 | 3 | 0.6 | 80 | 4.5 | 0.7 | 4.3 | 19 | 14 | right | 720 | 20 | |

| 90 | 3 1/2 | 90 | 99.6 | 0.2 | 3 | 0.6 | 90 | 4.8 | 0.8 | 4.5 | 20 | 14 | right | 810 | 20 |

| 100 | 100 | 109.6 | 0.2 | 3 | 0.6 | 100 | 4.8 | 0.8 | 4.6 | 24 | 14 | right | 920 | 20 | |

| 110 | 110 | 121 | 0.2 | 3 | 0.6 | 110 | 5.5 | 0.8 | 5.3 | 23 | 15 | right | 1120 | 20 | |

| 120 | 120.5 | 131.5 | 0.15 | 3 | 0.45 | 120 | 5.5 | 0.8 | 5.3 | 23 | 17.5 | right | 1180 | 20 | |

| 125 | 125.5 | 136.5 | 0.15 | 3 | 0.45 | 125 | 5.5 | 0.8 | 5.3 | 24 | 17.5 | right | 1250 | 20 | |

| 130 | 130 | 142 | 0.15 | 3 | 0.3 | 130 | 6 | 0.8 | 5.6 | 23 | 19 | right | 1350 | 20 | |

| 140 | 140 | 152 | 0.1 | 3 | 0.3 | 140 | 6 | 0.9 | 5.6 | 24 | 19 | right | 1500 | 20 | |

| 150 | 150.5 | 162.5 | 0.1 | 3 | 0.3 | 150 | 6 | 0.9 | 5.6 | 25 | 19.5 | right | 1600 | 20 | |

| 160 | 160 | 172.4 | 0.1 | 3 | 0.3 | 160 | 6.2 | 0.9 | 5.8 | 26 | 20 | right | 1780 | 20 | |

| 180 | 180 | 193 | 0.1 | 3 | 0.3 | 180 | 6.5 | 0.9 | 6.2 | 28 | 19.5 | right | 2100 | 10 | |

| 200 | 200 | 214 | 0.1 | 3 | 0.3 | 200 | 7 | 0.9 | 6.7 | 32 | 21.5 | right | 2280 | 10 | |

| 250 | 250 | 265 | 0.1 | 3 | 0.3 | 250 | 7.5 | 1 | 7.2 | 35 | 23 | right | 2960 | 10 | |

| 300 | 304.8 | 320 | 0.1 | 3 | 0.3 | 300 | 7.6 | 1.1 | 7.3 | 43 | 23 | right | 3850 | 10 |

All technical specifications apply to a temperature of 23° C ± 2° C (ISO 291)

The tolerance on all specifications ±5% (Tolerance Percentage is applicable on ALL DATA across our range)