Needle Roller Bearings

Needle Roller Bearings are mainly selected for constructions requiring reduced radial dimensions and maximum rigidity and load capacity. They have little resistance for axial forces (except Thrust and Combined bearings).

Roller and Cage Assemblies

A needle cage comprises an inseparable cage and needles and can be used to design very compact, light, constructions with maximum capacity. The shaft and housing act as a raceway and must be machined in compliance with hardness, geometry and roughness characteristics. The needles are guided precisely, therefore the needle cage can absorb much higher speeds of rotation than contact needles.

Material and Cage Variants

| Types | Characteristics | Suffixes |

|---|---|---|

| K | Fibre glass reinforced polyamide | -T2 |

| K or KJ | Welded pressed steel cage | -S |

| GK / GPK | In two parts | |

| K | Two rows | -ZW |

| KBK | For piston pins application | |

| KV | For piston pins application | -S |

| PK / GPK | For crank pins application | |

| KMJ | For crank pins application | -S |

Roller Thrust Bearings

Needle or roller thrust bearings are designed to absorb axial forces in one direction only. Support surfaces used as raceways must be ground and hardened.

Needle thrust bearings: type AXK11

Roller thrust bearings: series 811, 812, 874 and 893

- Available with Polyamide cage (-T2), Aluminium alloy cage (-: lightness and enhanced performance when lack of lubricant) or pressed steel cage

Washers:

- Type AS11 washers are thin (1 mm), therefore their support surfaces must be flat and rigid enough

- Types WS (centered on the shaft) and GS (centered on the housing) are more rigid

Drawn Cup Roller Bearings

Compact and light, mainly used in applications with low loads, needle sockets represent a low-cost bearing solution; the outer ring is not machined, but is obtained using precision pressing processes. It must be noted that the geometry of the raceway depends on the geometry of the housing (the low thickness of the outer ring only provides the hardness and roughness necessary for the raceway).

- Standard (HK) and heavy (HMK) series, available with or without sealing, with open or closed ends (BK, BMK)

- Some dimensions are delivered with 2 rows of needles (-ZW)

- Inches versions with cage (DCL, SCE) and contact needle versions (HCK)

- NTN drawn cup needle roller bearing offer:

- simplified adapting thanks to an ideal geometry

- an improved service life: specific treatment of the cage and needles

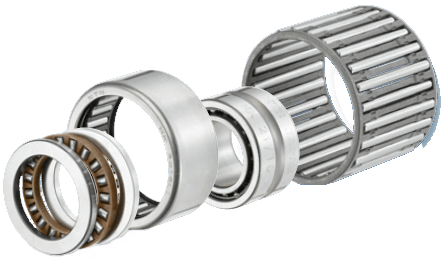

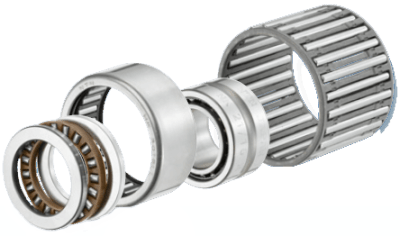

With Solid Rings

Needle roller bearings with solid rings are mainly used in applications with high loads.

Inseparable versions: with or without an inner ring

- Series 48, 49, 59 and 69. (Series 49 is also available with simple or double sealing)

- NK series: also deliverable with the inner ring (NK+IR designation). If the bearing is used without an inner ring, the shaft will act as a raceway and must be machined appropriately

Separable versions: RNAO and NAO

- With these versions, the inner and outer rings and the cage can be separated, opening up more assembly options.

- The inner rings are delivered separately

- Versions with plunge grinding for seal support surfaces are also available

- These solid rings and needle bearings are also available in inch dimensions. (MR,MI)

Bearing Number Example