Cleanly Solved with BRECOprotect Food Timing Belts

Cleanly Solved with BRECOprotect Food Timing Belts

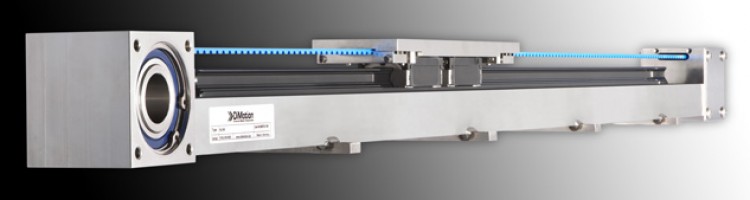

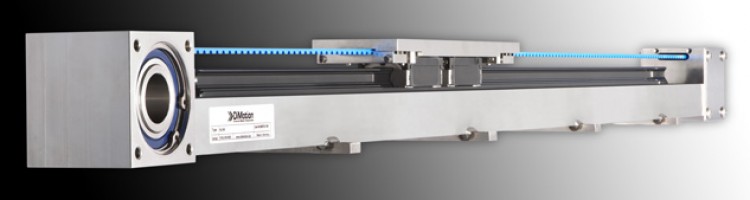

Rustproof linear module with timing belt drive suitable for use in the food industry

There are few industrial applications in which hygiene plays such an important role as in the food industry. Specialist food timing belts are required to meet the stringent requirements.

The German Engineering Federation (VDMA) estimates that the proportion of time spent on cleaning in the food industry is 20 to 30 percent. Hygienically designed machines for processing foodstuffs therefore offer huge potential savings thanks to shorter cleaning times, easier cleaning and maintenance, and a higher degree of safety.

Proven design features are smooth surfaces, as few edges as possible, no protruding threads, no small inside radii and no pockets if possible. Conventional linear modules for the food industry driven by timing belts meet most of these standards with regard to hygiene. The belt drive is enclosed inside a cast aluminium profile for several reasons. The timing belt and carriage are sealed from the outside by cover belts, scrapers and sealing strips – a proven but complex solution. The risk of contamination of the dead spaces in the profile cannot be completely prevented, which is why sealing or purge air is used to keep fluids and solids out in order to prevent the build up of bacteria. However, sealing or purge air in the food industry also has to meet particular requirements of purity (solids, water and oil content) if it comes into direct contact with food. As well as having to provide compressed air and the connection to the linear module, additional filter cascades may also be necessary.

Avoidance of dead spaces – open construction

DiMotion, specialist for linear technology, together with Mulco partner Walter Rothermundt GmbH & Co. KG, Mönchengladbach chose a different route: The avoidance of dead spaces and thus 100% hygiene control was the most important objective in the design of the new linear module. However, a non-enclosed mechanism requires the use of particularly corrosion- and chemical-resistant materials. Two special grades of stainless steel (1.4301, 1.4401) are available for the entire base structure of the LDMB80 modules, consisting of end elements and a U-shaped profile open at the bottom. During a short development time of only a few weeks these were replaced with open end elements. Each of the end elements can be driven by a geared servo motor. Two recirculating ball rails arranged in parallel are available to compensate for greater moments of tilt. Coated profile rails and profile rails made of stainless steel are available.

The precise BRECOprotect food timing belts in conjunction with the profile rail running in roller bearings achieve a positioning accuracy of 0.1 mm, depending on the load conditions. This system, offering a maximum stroke of 11000 mm and a speed of up to 4 m/s, meets the requirements of most applications.

The belt tensioning device and the clamping element are located on the slide – a simple and ingenious detail. In the enclosed modules, the non-driven end element normally accommodates two moveable bearing blocks on the side of the pulley. For this reason it is particularly important to ensure that the pulleys are precisely parallel when tensioning the belt. The LDMB80 modules are designed without this potential source of error – the belt is tensioned and clamped directly on the table; the centre to centre distance is fixed.

Thanks to the open design, not only are the pulleys and timing belts easily accessible for cleaning, but also the lubricant points for the recirculating ball carriages. Of course, food-grade FDA approved lubricant is used. Polished external surfaces and even an integrated measuring system are optionally available.

Drive element BRECOprotect® food timing belts

The open design is possible thanks to a drive belt that can tolerate all the mechanical and chemical stresses of daily cleaning and a moist environment. In particular, a suitable timing belt for this environment has to meet the following three requirements:

- Optimum resistance to cleaning agents

- Very good hydrolysis resistance

- Excellent resistance to microbes.

Microbes and their toxins that come into contact with food can lead to food poisoning. So Rothermundt selected the polyurethane food timing belt BRECOprotect® 32AT10 for DiMotion. These timing belts are specifically designed for food processing and packaging. The elastomer TPUAU 1-blue meets the conformity criteria of the FDA CFR § 177.1680 (as well as the EC directives 90/128/CEE and 96/11/CE). The blue colour of the polyurethane makes it clearly identifiable for the customer as being suitable for use in the food industry. Contamination adhering to the surface is easy to detect.

BRECOprotect® food timing belts are manufactured without the typical coiling nose. The steel tension members are completely enclosed in polyurethane. This protects them from corrosion and prevents hidden or hard-to-remove contamination. The blue timing belts for the food industry are available in the profile types AT10, AT15 and T10 with belt widths of 25 to 100 mm.

In drive technology, there is no “one size fits all” solution, but an optimum solution for a particular application according to the respective constraints. In addition to the proven enclosed linear modules, there is now an interesting open design variant – with guaranteed resistance of the timing belt for machines in moist or wet environments, in food packaging applications and for use in laboratories.