Bushes

- Taper Bushes

- Metric & Imperial

- Shaft Locking Elements

- Self centering variants

- Keyless locking variants

- Steel and Stainless Steel

FAQs

What is a Bush/Bushing?

A Bush or Bushing is a fixed or removable cylindrical tube or sleeve that provides an interface between two parts. It is used to constrain, guide, or reduce friction and is effectively one classification of the overall category of bearings and may also be referred to as a Sleeve Bearing or Plain Bearing. Common designs of Bushes include solid (sleeve and flanged), split, and clenched bushings.

How does a Bush/Bushing work?

Bushings operate with a sliding motion between the moving surfaces, typically relying on soft metal or plastic and an oil film. This combination supports the rotating shaft on the hardened shaft journal. They are usually pushed in when fitting.

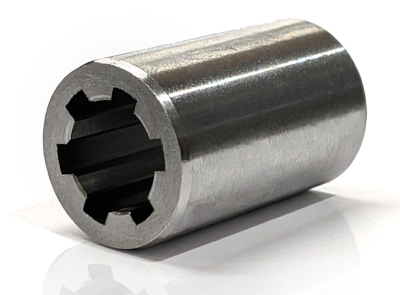

What does a Bush/Bushing look like?

sleeve, split, or clenched Bushes and Bushings are a “sleeve” of material with an inner diameter (ID), outer diameter (OD), and length. A solid Sleeved Bushing is solid all the way around whereas a Split Bushing has a cut along its length. A Clenched Bushing is similar to a Split Bushing, but with a clench (or clinch) across the cut connecting the parts.

What does a Bush/Bushing do?

Bushes damp the energy transmitted through the Bushing by reducing the friction between rotating shafts and stationary support members. Bushings are suitable for rotating, oscillating and linear movements.

Where is a Bush/Bushing used?

A common application is in vehicle suspension systems, where a Bushing made of rubber (or, more often, synthetic rubber or polyurethane) separates the faces of two metal objects, while allowing a certain amount of movement. Bushings are selected based on the velocity and the applied load. Maintenance-free bushings do not require additional lubrication to operate.

Good to know about Bushings?

Whereas straight (cylindrical) Bushings can accommodate radial loads only, flanged bushings can accommodate both radial and axial loads in one direction. The varied combinations of Bushing designs and materials deliver characteristic properties that make them suitable for a wide range of applications.