Spiralina Hose Protection (926003)

| SPIRAL GUARD SERIES |

|

Spiralina Hose Protector (926003) is a rigid PVC spiral SH. D. (3 SEC.) = 78 ± 3, for protection from crushing and abrasion (in compliance with ISO 4649 < 150 mm3) of hydraulic hoses, bundling of hoses and cables.

Spiral Guard Series products were created to protect a single hose or bundle and protect a number of hoses and cables. Using Spiralina products helps avoid crushing and abrasion of cables and hoses. Cables and hoses are also easy to insert and remove with no fitting disassembly required. Spiral Guard Series products are manufactured by extrusion of a profile in a rigid thermoplastic material, brought on a mandrel then, keeping each turn of the profile at the right distance, a spiral is shaped.

Details

| Features | Value | |

|

Smooth surface | ***** |

|

Flexibility | **** |

|

Abrasion resistance | **** |

|

Temperature range | -10 °C 60 °C |

|

Chemical Resistance | Contact TransDev |

|

Crushing resistance | ***** |

|

Ozone resistance | **** |

|

Flame retardant | Plastic material according to UL 94 V0 |

|

Anti UV | >200 h |

|

Compression Load | ≥130 |

|

Method of Calculation | (OUTSIDE hose Ø mm / INSIDE spiral Ø mm) x hose length mt = spiral mt |

Specification

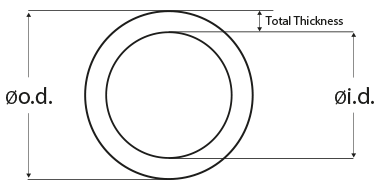

Ø Nominal |

Ø i.d. |

Ø o.d. |

For single hoses

|

For hoses in bundles o.d. Min-max |

Wall thickness |

Spiral pitch |

Weight

|

Compression load for red. 1/3 Ø o.d. |

Tensile force needed

|

Coil length |

|---|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | inch | mm | mm | mm | g/m | kg | kg | m |

| 13×16 | 13 | 16 | 3/16″ – 1/4″ | 12 – 18 | 1.5 | 10.5 | 80 | >=130 | >3 | 20 |

| 16×20 | 16 | 19.4 | 1/4″ – 1/2″ | 16 – 26 | 1.7 | 12 | 100 | >=130 | >3 | 20 |

| 20×25 | 20 | 24.2 | 1/2″ – 3/4″ | 20 – 27 | 2.1 | 14.5 | 170 | >=130 | >3 | 20 |

| 24×29 | 23.5 | 28.5 | 1/2″ – 3/4″ | 23 – 30 | 2.5 | 15 | 240 | >=130 | >4 | 20 |

| 25×30 | 26 | 31 | 1/2″ – 1″ | 25 – 33 | 2.5 | 16 | 250 | >=130 | >4 | 20 |

| 27×32 | 27 | 32.2 | 5/8″ – 1″ | 27 – 35 | 2.6 | 16 | 295 | >=130 | >4 | 20 |

| 30×35 | 30 | 35.4 | 3/4″ – 1″ | 30 – 35 | 2.7 | 18 | 330 | >=130 | >4 | 20 |

| 35×40 | 35 | 40.6 | 1″ – 1″1/4 | 35 – 60 | 2.8 | 20.5 | 420 | >=130 | >4 | 20 |

| 44×50 | 44 | 50 | 1″ 1/4″ – 1″1/2 | 35 – 75 | 3 | 21.5 | 600 | >=130 | >4 | 20 |

| 56×63 | 56 | 63 | 1″ 1/2″ – 2″ | 50 – 90 | 3.5 | 26 | 850 | >=130 | >4 | 20 |

| 65×75 | 65 | 74 | 2″ | 60 – 120 | 4.5 | 29 | 1150 | >=130 | >5 | 20 |

| 80×90 | 80 | 90 | 2″1/2 | 75 – 200 | 5 | 35 | 1600 | >=130 | >5 | 20 |

| 100×112 | 103 | 113 | 3″ | 90 – 220 | 5.5 | 46 | 2200 | >=130 | >5 | 10 |

| 120×132 | 124 | 136 | 4″ | 110 – 240 | 6 | 50 | 2850 | >=130 | >5 | 10 |

All technical specifications apply to a temperature of 23° C ± 2° C (ISO 291)

The tolerance on all specifications ±5% (Tolerance Percentage is applicable on ALL DATA across our range)