Armorvin HNP Hose (913030)

| ARMORVIN SERIES |

|

Armorvin HNP Hose (913030) is a soft PVC hose with embedded galvanized steel spiral for suction and delivery of food liquids. Heavy duty version.

Details

| Features | Value | |

|

Smooth surface | ***** |

|

Flexibility | **** |

|

Abrasion resistance | *** |

|

Temperature range | -5 °C 65 °C |

|

Chemical Resistance | Contact TransDev |

|

Crushing resistance | *** |

|

For food | EU according to Declaration of Conformity. Contact TransDev. |

Specification

Ø Nominal |

Ø Nominal |

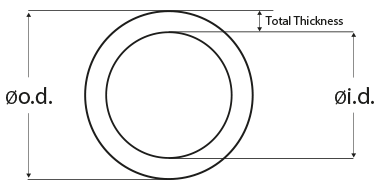

Ø i.d. |

Ø o.d. |

Vacuum 23 °C |

Working press. at 23 °C r.1:3 |

Bursting press. at 23 °C |

Bending radius |

Total thickness |

Ø Steel wire |

Spiral pitch |

Spiral direction |

Weight meter |

Segment length |

Coil length |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

mm |

inch |

mm |

mm |

m/H2O |

bar |

bar |

mm |

mm |

mm |

mm |

left/right |

g/m |

m |

m |

| 10 | 3/8 | 10 | 16 | 9.5 | 7 | 21 | 20 | 3 | 0.8 | 6.5 | right | 155 | 60 | |

| 12 | 12 | 18 | 9.5 | 7 | 21 | 25 | 3 | 0.8 | 7 | right | 180 | 60 | ||

| 14 | 14 | 20 | 9.5 | 6 | 18 | 30 | 3 | 0.8 | 7.5 | right | 200 | 60 | ||

| 16 | 5/8 | 16 | 22 | 9.5 | 6 | 18 | 35 | 3 | 0.8 | 7.5 | right | 225 | 60 | |

| 18 | 18 | 24.5 | 9.5 | 6 | 18 | 40 | 3.3 | 1 | 8 | right | 280 | 60 | ||

| 20 | 20 | 27 | 9.5 | 5 | 15 | 50 | 3.5 | 1 | 8 | right | 340 | 60 | ||

| 22 | 7/8 | 22 | 29 | 9.5 | 5 | 15 | 55 | 3.5 | 1 | 8.5 | right | 360 | 60 | |

| 25 | 1 | 25 | 33.5 | 9.5 | 5 | 15 | 60 | 4.3 | 1.4 | 13.5 | right | 510 | 60 | |

| 30 | 30 | 40 | 9.5 | 5 | 15 | 70 | 5 | 1.4 | 14.5 | right | 680 | 60 | ||

| 32 | 1 1/4 | 32 | 42 | 9.5 | 4.5 | 13.5 | 75 | 5 | 1.4 | 14.5 | right | 730 | 60 | |

| 35 | 35 | 44.5 | 9.5 | 4.5 | 13.5 | 80 | 4.8 | 1.4 | 14.5 | right | 730 | 60 | ||

| 38 | 1 1/2 | 38 | 49 | 9.5 | 4.5 | 13.5 | 90 | 5.5 | 1.6 | 15 | right | 950 | 30 | |

| 40 | 40 | 53 | 9.5 | 4 | 12 | 100 | 6.5 | 2 | 17 | right | 1220 | 30 | ||

| 45 | 1 3/4 | 45 | 58.5 | 9.5 | 4 | 12 | 110 | 6.75 | 2 | 18 | right | 1400 | 30 | |

| 50 | 2 | 50 | 63.5 | 9 | 4 | 12 | 125 | 6.8 | 2 | 18 | right | 1600 | 30 | |

| 60 | 60 | 74 | 9 | 3.5 | 10.5 | 140 | 7 | 2.5 | 20 | right | 2050 | 30 | ||

| 63 | 2 1/2 | 63 | 78 | 9 | 3.5 | 10.5 | 150 | 7.5 | 2.5 | 20 | right | 2250 | 30 | |

| 70 | 70 | 86 | 9 | 3.5 | 10.5 | 180 | 8 | 2.5 | 20 | right | 2600 | 30 | ||

| 75 | 75 | 91 | 9 | 3 | 9 | 200 | 8 | 2.5 | 17 | right | 2850 | 30 | ||

| 80 | 80 | 96 | 9 | 3 | 9 | 220 | 8 | 2.5 | 17.5 | right | 3150 | 30 | ||

| 90 | 3 1/2 | 90 | 107 | 9 | 3 | 9 | 260 | 8.5 | 3 | 18 | right | 3750 | 30 | |

| 100 | 100 | 118 | 9 | 3 | 9 | 300 | 9 | 3 | 18.5 | right | 4400 | 30 | ||

| 105 | 105 | 122 | 9 | 2 | 6 | 310 | 8.5 | 2.5 | 19.5 | right | 3900 | 20 | ||

| 110 | 110 | 128 | 9 | 3 | 9 | 320 | 9 | 3 | 19 | right | 4650 | 20 | ||

| 120 | 120 | 138 | 9 | 2 | 6 | 340 | 9 | 3 | 19.5 | right | 5200 | 20 | ||

| 125 | 125 | 144 | 9 | 2 | 6 | 350 | 9.5 | 3 | 19.5 | right | 5400 | 20 | ||

| 150 | 150 | 170 | 9 | 2 | 6 | 450 | 9.5 | 3 | 18 | right | 7200 | 20 | ||

| 203 | 8 | 202 | 224 | 9 | 2 | 6 | 900 | 11 | 3 | 19.5 | right | 9000 | 10 |

All technical specifications apply to a temperature of 23° C ± 2° C (ISO 291)

The tolerance on all specifications ±5% (Tolerance Percentage is applicable on ALL DATA across our range)