Termoresistente PU 200°C Hose (912955)

| SUPERFLEX SERIES |

|

Termoresistente PU 200°C Hose (912955) is a thermoplastic hose made of polyester textile coated with PU with galvanised steel spiral embedded between two layers of textile, for suction and ducting of hot air.

Details

| Features | Value | |

|

Smooth surface | *** |

|

Flexibility | **** |

|

Abrasion resistance | ***** |

|

Temperature range | -40 °C 200 °C |

|

Chemical resistance | Contact TransDev |

|

Crushing resistance | *** |

|

Tear resistance | ***** |

|

Perforation resistance | ***** |

|

Flame retardant | Fire class M1 according to article 5 of decree of 21.11.2002 (French regulations) and UL94 VTMO class.) |

Specification

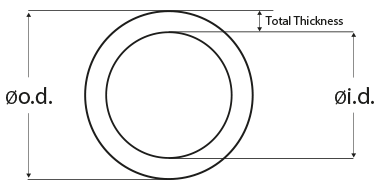

Ø Nominal |

Ø Nominal |

Ø i.d. |

Ø o.d. |

Vacuum

|

Bending

|

Wall

|

Ø Steel

|

Spiral

|

Spiral

|

Weight

|

Coil length |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | mm | m/H2O | mm | mm | mm | mm | g/m | m | |

| 38 | 39 | 44 | 9 | 19 | 0.4 | 1×1.4 | 15 | right | 165 | 15-30 | |

| 40 | 41 | 45 | 0.98 | 40 | 0.35 | 1.2 | 14 | left | 185 | ||

| 51 | 2 | 51 | 56 | 0.95 | 50 | 0.35 | 1.2 | 14 | left | 225 | 12 |

| 63 | 2 1/2 | 64 | 68 | 0.9 | 60 | 0.35 | 1.2 | 14 | left | 275 | 12 |

| 70 | 71 | 75 | 0.85 | 70 | 0.35 | 1.2 | 14 | left | 300 | 12 | |

| 76 | 3 | 77 | 81 | 0.8 | 75 | 0.35 | 1.2 | 14 | left | 320 | 12 |

| 83 | 84 | 88 | 0.75 | 80 | 0.35 | 1.2 | 14 | left | 360 | 12 | |

| 89 | 3 1/2 | 90 | 94 | 0.7 | 90 | 0.35 | 1.2 | 14 | left | 385 | 12 |

| 102 | 4 | 103 | 107 | 0.65 | 100 | 0.35 | 1.4 | 16 | left | 480 | 12 |

| 114 | 115 | 119 | 0.55 | 110 | 0.35 | 1.4 | 16 | left | 540 | 12 | |

| 121 | 122 | 126 | 0.5 | 120 | 0.35 | 1.4 | 16 | left | 580 | 12 | |

| 127 | 5 | 128 | 132 | 0.45 | 125 | 0.35 | 1.4 | 16 | left | 600 | 12 |

| 133 | 134 | 138 | 0.4 | 130 | 0.35 | 1.4 | 16 | left | 620 | 12 | |

| 140 | 141 | 146 | 0.38 | 140 | 0.35 | 1.4 | 16 | left | 660 | 12 | |

| 152 | 6 | 153 | 158 | 0.35 | 150 | 0.35 | 1.6 | 18 | left | 780 | 12 |

| 178 | 179 | 184 | 0.25 | 180 | 0.35 | 1.6 | 18 | left | 920 | 12 | |

| 203 | 8 | 204 | 209 | 0.2 | 200 | 0.35 | 1.6 | 18 | left | 1050 | 12 |

| 230 | 229 | 235 | 0.15 | 230 | 0.35 | 1.8 | 18 | left | 1350 | 12 | |

| 254 | 10 | 255 | 261 | 0.12 | 250 | 0.35 | 1.8 | 18 | left | 1500 | 12 |

| 305 | 12 | 306 | 312 | 0.1 | 300 | 0.35 | 1.8 | 18 | left | 1800 | 6 |

| 315 | 318 | 324 | 0.09 | 315 | 0.35 | 2 | 22 | left | 1860 | ||

| 350 | 354 | 360 | 0.08 | 350 | 0.35 | 2 | 22 | left | 2060 | ||

| 400 | 406 | 412 | 0.06 | 400 | 0.35 | 2 | 22 | left | 2360 |

All technical specifications apply to a temperature of 23° C ± 2° C (ISO 291)

The tolerance on all specifications ±5% (Tolerance Percentage is applicable on ALL DATA across our range)