Superflex PU AllRounDuct 04 Hose (914002)

| SUPERFLEX SERIES |

|

Superflex PU AllRounDuct 04 Hose (914002) is a ducting with constant wall thickness of 0.4 mm, made of antistatic polyether PU, flame retardant according to DIN 4102-B1, reinforced with a right pitch copper plated PU covered steel spiral. For suction and delivery of abrasive materials, in applications where static electricity can be an issue.

Details

| Features | Value | |

|

Smooth surface | *** |

|

Flexibility | **** |

|

Abrasion resistance | ***** |

|

Temperature range | -40 °C 90 °C |

|

Chemical resistance | Contact TransDev |

|

Crushing resistance | *** |

|

Ozone resistance | ***** |

|

Microorganisms resistance | ***** |

|

Flame retardant | According to DIN -4102 IN B1 class |

|

ATEX | According to the directions for use |

|

Hydrolysis resistance | Resistant to hydrolysis in 60 °C warm water |

|

O-Phtalate free | ***** |

|

Phtalate free | ***** |

Specification

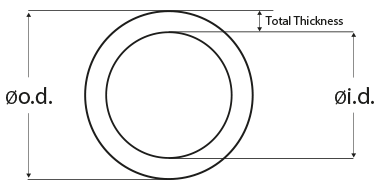

Ø Nominal |

Ø Nominal |

Ø i.d. |

Ø o.d. |

Vacuum

|

Bending

|

Wall

|

Ø Steel

|

Spiral

|

Spiral

|

Weight

|

Coil length |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | mm | m/H2O | mm | mm | mm | mm | g/m | m | |

| 38 | 39 | 44 | 9 | 19 | 0.4 | 1×1.4 | 15 | right | 165 | 15-30 | |

| 40 | 41 | 46 | 9 | 20 | 0.4 | 1×1.4 | 15 | right | 175 | 15-30 | |

| 51 | 2″ | 52 | 57 | 9 | 25 | 0.4 | 1.2×1.6 | 16 | right | 250 | 15-30 |

| 60 | 61 | 66 | 9 | 30 | 0.4 | 1.2×1.6 | 16 | right | 300 | 15-30 | |

| 63 | 2″ 1/2 | 64 | 69 | 7.5 | 31 | 0.4 | 1.2×1.6 | 16 | right | 310 | 15-30 |

| 65 | 66 | 71 | 7.5 | 32 | 0.4 | 1.2×1.6 | 16 | right | 320 | 15-30 | |

| 70 | 71 | 76 | 7 | 35 | 0.4 | 1.2×1.6 | 16 | right | 340 | 15-30 | |

| 76 | 3″ | 77 | 83 | 7 | 38 | 0.4 | 1.4×1.8 | 16 | right | 420 | 15-30 |

| 80 | 81 | 87 | 6.5 | 40 | 0.4 | 1.4×1.8 | 16 | right | 430 | 15-30 | |

| 90 | 91 | 97 | 4 | 45 | 0.4 | 1.4×1.8 | 16 | right | 490 | 15-30 | |

| 102 | 4″ | 103 | 109 | 3.5 | 51 | 0.4 | 1.4×1.8 | 18 | right | 530 | 15-30 |

| 110 | 111 | 117 | 3 | 55 | 0.4 | 1.4×1.8 | 18 | right | 600 | 15-30 | |

| 120 | 121 | 127 | 2 | 60 | 0.4 | 1.4×1.8 | 18 | right | 630 | 15-30 | |

| 127 | 5″ | 128 | 134 | 2 | 63 | 0.4 | 1.4×1.8 | 18 | right | 650 | 15-30 |

| 130 | 131 | 137 | 2 | 65 | 0.4 | 1.4×1.8 | 18 | right | 665 | 15-30 | |

| 140 | 141 | 147 | 1.5 | 70 | 0.4 | 1.4×1.8 | 18 | right | 720 | 15-30 | |

| 152 | 6″ | 153 | 160 | 2.5 | 76 | 0.4 | 1.8×2.2 | 22 | right | 900 | 15-30 |

| 160 | 161 | 168 | 2 | 80 | 0.4 | 1.8×2.2 | 22 | right | 940 | 15-30 | |

| 180 | 181 | 188 | 1.5 | 90 | 0.4 | 1.8×2.2 | 22 | right | 1080 | 15-30 | |

| 200 | 201 | 208 | 1 | 100 | 0.4 | 1.8×2.2 | 22 | right | 1200 | 15-30 | |

| 203 | 8″ | 204 | 211 | 1 | 100 | 0.4 | 1.8×2.2 | 22 | right | 1220 | 15-30 |

| 220 | 221 | 228 | 0.5 | 110 | 0.4 | 1.8X2.2 | 22 | right | 1300 | 15 | |

| 250 | 251 | 258 | 0.5 | 125 | 0.4 | 2×2.5 | 22 | right | 1600 | 15 | |

| 254 | 10″ | 255 | 262 | 0.5 | 125 | 0.4 | 2×2.5 | 22 | right | 1650 | 15 |

| 300 | 301 | 308 | 0.2 | 150 | 0.4 | 2×2.5 | 22 | right | 1850 | 15 |

All technical specifications apply to a temperature of 23° C ± 2° C (ISO 291)

The tolerance on all specifications ±5% (Tolerance Percentage is applicable on ALL DATA across our range)