Superflex PU CHR Hose (912831)

| SUPERFLEX SERIES |

|

Superflex PU CHR Hose (912831) is a polyurethane (PU) hose with copper-plated steel spiral, for suction and transport of dust, chips and abrasive material.

Details

| Features | Value | |

|

Smooth surface | *** |

|

Flexibility | ***** |

|

Abrasion resistance | ***** |

|

Temperature range | -40 °C 90 °C |

|

Chemical resistance | Contact TransDev |

|

Crushing resistance | *** |

|

Ozone resistance | ***** |

|

For food | EU according to Declaration of Conformity. FDA according to Declaration of Conformity |

|

O-Phtalate free | ***** |

|

Phtalate free | ***** |

Specification

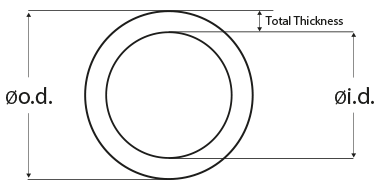

Ø Nominal |

Ø Nominal |

Ø

|

Ø o.d. |

Vacuum

|

Bending

|

Wall

|

Ø Steel

|

Spiral

|

Spiral

|

Weight

|

Coil length |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | mm | m/H2O | mm | mm | mm | mm | g/m | m | |

| 38 | 39 | 44 | 9 | 19 | 0.4 | 1×1.4 | 15 | right | 165 | 15-30 | |

| 25 | 1 | 25.5 | 28.5 | 0.4 | 50 | 0.3 | 1 | 7 | right | 130 | 30 |

| 30 | 30.5 | 33.5 | 0.4 | 60 | 0.3 | 1 | 8 | right | 145 | 30 | |

| 32 | 32.5 | 35.5 | 0.35 | 65 | 0.3 | 1 | 8 | right | 150 | 30 | |

| 35 | 35.5 | 38.5 | 0.28 | 70 | 0.3 | 1 | 8 | right | 160 | 30 | |

| 38 | 38.5 | 41.5 | 0.25 | 75 | 0.35 | 1 | 8.5 | right | 180 | 30 | |

| 40 | 40.5 | 44 | 0.23 | 80 | 0.35 | 1 | 8.5 | right | 190 | 30 | |

| 45 | 1 3/4 | 45.5 | 49 | 0.2 | 90 | 0.35 | 1 | 9.5 | right | 200 | 30 |

| 50 | 50.5 | 54 | 0.18 | 100 | 0.35 | 1 | 9.5 | right | 215 | 30 | |

| 51 | 2 | 51.5 | 55 | 0.18 | 100 | 0.35 | 1 | 9.5 | right | 220 | 30 |

| 55 | 55.5 | 59 | 0.15 | 110 | 0.35 | 1 | 9.5 | right | 240 | 30 | |

| 60 | 60.5 | 64 | 0.14 | 120 | 0.35 | 1 | 10.5 | right | 250 | 30 | |

| 63 | 2 1/2 | 63.5 | 67 | 0.1 | 125 | 0.35 | 1 | 10.5 | right | 260 | 30 |

| 65 | 65.5 | 69 | 0.1 | 130 | 0.35 | 1 | 10.5 | right | 270 | 30 | |

| 70 | 70.5 | 75 | 0.1 | 140 | 0.35 | 1.3 | 12.5 | right | 320 | 30 | |

| 75 | 75.5 | 80 | 0.09 | 150 | 0.35 | 1.3 | 12.5 | right | 360 | 30 | |

| 76 | 3 | 76.5 | 81 | 0.09 | 155 | 0.35 | 1.3 | 12.5 | right | 360 | 30 |

| 80 | 80.5 | 85 | 0.09 | 160 | 0.4 | 1.3 | 14 | right | 400 | 30 | |

| 90 | 3 1/2 | 91 | 96 | 0.09 | 180 | 0.4 | 1.3 | 14.5 | right | 420 | 30 |

| 100 | 101 | 106 | 0.08 | 200 | 0.4 | 1.3 | 15.5 | right | 430 | 30 | |

| 102 | 4 | 103 | 108 | 0.08 | 205 | 0.4 | 1.3 | 15.5 | right | 440 | 30 |

| 110 | 111 | 116 | 0.08 | 220 | 0.4 | 1.3 | 16 | right | 460 | 30 | |

| 120 | 121 | 126 | 0.06 | 240 | 0.4 | 1.3 | 16 | right | 480 | 30 | |

| 125 | 126 | 131 | 0.06 | 250 | 0.4 | 1.3 | 16 | right | 540 | 30 | |

| 130 | 131 | 136 | 0.06 | 260 | 0.4 | 1.3 | 16 | right | 580 | 30 | |

| 140 | 141 | 146 | 0.06 | 280 | 0.4 | 1.3 | 16 | right | 600 | 30 | |

| 150 | 153 | 158 | 0.05 | 300 | 0.4 | 1.6 | 17 | right | 800 | 30 | |

| 160 | 161.5 | 166 | 0.05 | 320 | 0.4 | 1.6 | 18 | right | 820 | 30 | |

| 180 | 183.5 | 188 | 0.04 | 360 | 0.4 | 1.6 | 20 | right | 900 | 20 | |

| 200 | 204 | 209 | 0.04 | 400 | 0.4 | 1.6 | 20 | right | 980 | 20 | |

| 250 | 254 | 260 | 0.03 | 500 | 0.45 | 1.8 | 22 | right | 1460 | 10 | |

| 300 | 306 | 312 | 0.03 | 600 | 0.45 | 1.8 | 28 | right | 1560 | 10 |

All technical specifications apply to a temperature of 23° C ± 2° C (ISO 291)

The tolerance on all specifications ±5% (Tolerance Percentage is applicable on ALL DATA across our range)